Reduce recipe costs while maintaining excellent textures and flavors in your dairy products with BDF Transglutaminase

The FAO Dairy Price Index rose 5.5 percent in May, an upsurge of 11.5 percent when compared to last year’s figures. The shortage of supplies from New Zealand – the world’s largest exporter of dairy products – is the main reason for the market fluctuations of the last few months.

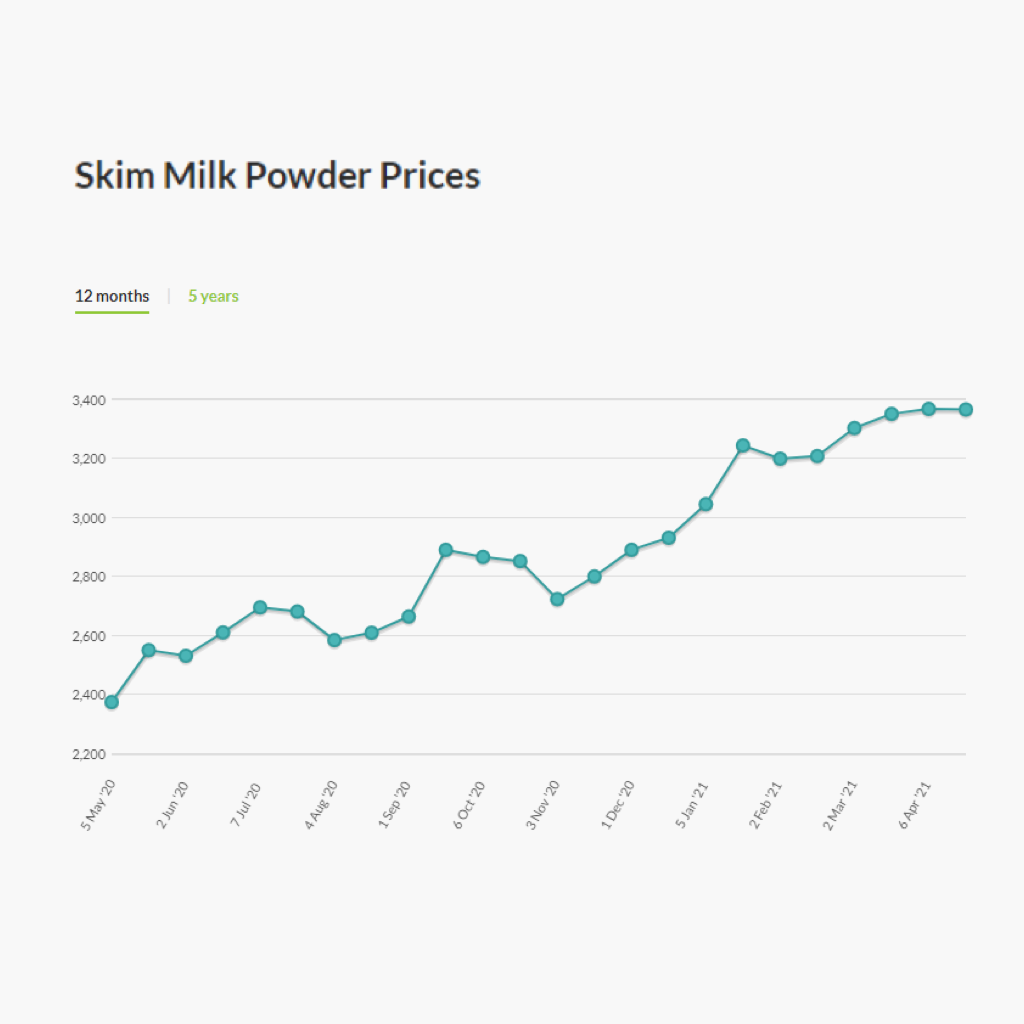

As shown in the graph, dairy products, such as milk powder or butter, have become increasingly more expensive over the last twelve months, with prices that have now raised by practically 50%. These circumstances are forcing clients to compensate for these added costs by reducing their commercial margins, or by increasing the price of their products, which in the end run affects their appeal to consumers.

As such, these price increases are a formidable argument in favor of seeking technological alternatives that help reduce the impact raw material cost fluctuations, and this is where BDF’s PROBIND® CH 2.0 comes into play. This product is based on the Transglutaminase enzyme and has been specifically designed for dairy applications. By creating strong covalent bonds between proteins, the use of certain raw materials can be reduced, yet without any loss in terms of creaminess, texture or flavor. And what’s more, it’s a highly cost-effective solution.

The graphs below show how a 2% fat reduction can be applied, in a process that improves viscosity and creaminess, while improving the product’s sensory profile. By reducing fat the product obtains a better Nutri-score. Excess fat in value-added products such as butter can also be modified.

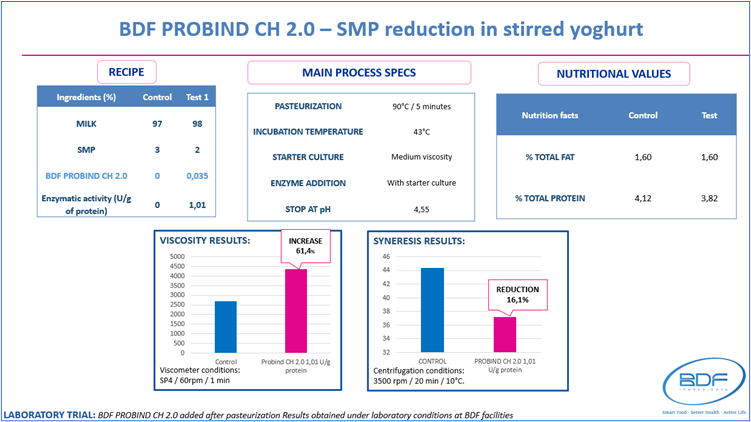

Another process extensively used by our clients involves reducing milk solids; in this case a stirred yogurt with powdered milk, with a reduction in milk powder from 3% to 2% on the application of BDF PROBIND® CH 2.0 to the formula. This translates into a considerable cost reduction, while improving results in terms of viscosity, creaminess and syneresis, as shown below:

Cost reduction, together with specific improvements in a product’s physical and sensory properties are some of the most popular features demanded by BDF’s main clients. You are more than welcome to perform trials at your own facilities to verify the results of our applications for yourself. Request your samples from our website at info@bdfingredients.com and we will be happy to advise you during the testing process.